“The circularity of our SKF solutions is very important and we pride ourselves on being a market leader in the sustainable development of bearing and power transmission products and solutions,” begins Micaela Willers, SKF SA’s manager for power transmission and training. This is highlighted by the recent development of the bar-setting SKF Infinium bearing design, which can be remanufactured an indefinite number of times using a unique cladding technology.

Click to download and read pdf

“Together with AI technology, once a defect has been detected, the life and the root cause can be determined so that a scheduled and safe removal, remanufacture and reassembly can be arranged,” Willers explains.

“Using advanced Laser Metal Deposition (LMD) technology, our new SKF Infinium bearings can be reclad and reused repeatedly, marking a significant advancement in circularity and additive manufacturing,” Willers explains, adding that there is no limit to the number of times these bearings can be re-manufactured.

“By promoting circularity in this way, we are trying to change the way people see bearings: from being a consumable discarded when ‘spent’; to being a high-value asset that needs to be nurtured and serviced, then remanufactured to its as-new condition as soon as its performance starts to dip,” she explains.

“While we don't have a timeline for introducing this new level of remanufacturing into South Africa, we do already have a strong manufacturing service for larger bearings, which already has a long history in South Africa,” she says, adding that SKF SA is currently working to establish a bearing remanufacturing centre specifically for the railway industry.

On the emissions side, Micaela Willers says that, together with the Nordic steel producer, Ovako, SKF can now produce spherical roller bearing (SRB) with 90% less embedded carbon compared to standard SRB bearings. This by using a high-quality bearing steel produced from 97% recycled steel and manufactured in SKF’s net zero factory in Gothenburg, Sweden.

Globally, she says: SKF is now aiming to achieve a fully carbon neutral manufacturing footprint by 2030, while achieving net-zero emissions across the supply chain by 2050. To achieve this the company is involved in several initiatives with various steel producers to actively reduce production-linked emissions. This includes the use of hydrogen direct reduced iron (H-DRI), a breakthrough in decarbonising all the steel used to produce its bearings.

“Our new company purpose is that together, we reimagine rotation for a better tomorrow. This is now embedded deep into SKF’s DNA, influencing all the decisions and changes we make, from the design and manufacture of our products to the solutions and services we offer to industry,” she adds.

As well as being a global leader when it comes to taking care of the environment, bearing quality, knowledge and development have long been cornerstones of the company’s success. “We have developed advanced products and services to help clients reduce the total cost of ownership of the bearing we provide. This includes mechanical field services, engineering services, condition monitoring and remanufacturing: all delivered in time to prevent bearings from failing catastrophically.

“Compared to the circular approach to investing in and looking after a high quality and fit for purpose asset, the consumable approach – throwing away and replacing bearings when they wear out – is expensive over a machine’s life. In addition, if inferior quality consumable products are chosen to reduce costs, the risks of an expensive machine repair can be crippling,” she argues.

“Seeing bearings as an asset that needs to be managed results in plant operators seeing the value of utilising the services provided by SKF, which are key to reducing the total cost of ownership and extending the life of chosen assets. We strive to look at the full lifecycle of an installation. Choosing the correct bearing and installing it correctly are of utmost importance. If a mistake occurs here, then the life could be immediately impaired.

“During operation, lubrication systems and management must be applied to ensure that bearings receive the correct lubricant at the right time. We are then able to monitor the health of the bearing and the machine, using one of our suitable condition monitoring systems. Together with AI technology, once a defect has initiated and been detected, the remaining life and the root cause can be determined, so that a scheduled and safe removal, remanufacture and reassembly can be arranged,” Willers explains.

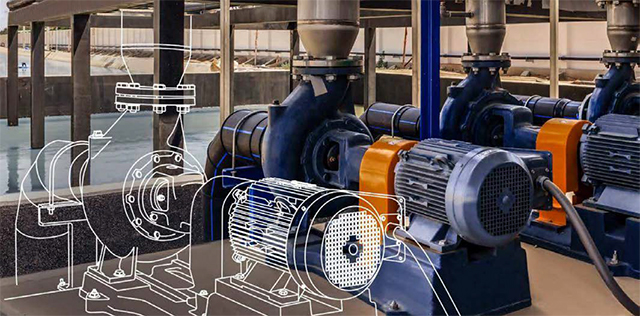

Engineered transmission solutions

Re-imagining rotation can also involve making improvements to the transmission systems of installed equipment. “We strive to look beyond simply replacing a bearing, belt or a chain, for example. By looking at a machine holistically, at the power ratings, speeds and torques, for example, we can often optimise machine performance as well as making it run more efficiently,” she continues. “Compact, right-sized transmission systems that use modern high-performance components can often take the load off electric motors and gearboxes.”

Describing a retrofit solution for a belt drive on a slurry pump, Willers says that, together, the original motor pulley, pump pulley and belts weighed almost 140 kg. “We redesigned the whole belt drive around SKF raw-edge EPDM synthetic rubber V-belts, which have ‘cushions on their inside surfaces to enable the belts to be more flexible around smaller pulleys. These belts provide higher friction and lower power losses due to slippage, while the rubber cushioning significantly increases the life of belts, particularly if operating at high ambient temperatures.

“With smaller drive wheels and shorter belts, we were able to bring the mass of the whole drive down to 64 kg. The grooves were narrower and there were fewer of them, but we were able to transfer the same about of power to the pump from a smaller motor. This resulted in a substantial cost saving on the motor, but more importantly, a massive energy saving over the life of the pump.

“We are currently doing something similar for a chain drive for a conveyor in the pulp and paper industry. We are taking almost 180 kg off the conveyor, just by changing the chain for a thinner, lighter one that can handle the same tension. That opens opportunities to look at the whole drive train: the cogs, the gearbox, motors and the bearings. By optimising the whole drive using due diligence and fit-for-for purpose sizing of every component, the conveyor becomes lighter, smaller, less expensive upfront, and much more energy efficient,” Micaela Willers points out.

She says that in the power generation industry, the same applies to some of the massive couplings that are in use, which can weigh up to 500 kg each, driven by gearboxes the size of rooms. By switching to modern materials and component designs, significant savings and performance improvements can be achieved,” she points out.

“Optimisation, of whole rotating systems, is key. If an entire system can be re-engineering to better suit the exact torque and drive requirements, then smaller bearings and power transmission components can all be made to run more efficiently, waste less energy and last a lot longer.”

“And if those components are manufactured with the planet in mind, then together, we are moving towards a better tomorrow,” she concludes.