Enrico Zuin, Nazmi Adams and Herbert Abbott of voestalpine Böhler Welding present their company’s welding solutions in support of carbon capture, utilisation and storage (CCUS).

Click to download and read pdf

Carbon dioxide (CO2) emissions resulting from human activities, particularly from the combustion of fossil fuels, have led to atmospheric CO2 concentrations in the earth’s atmosphere rising from pre-industrial levels of around 280 ppm to a current average of 420 ppm. While this may not sound like much, anthropogenic emissions have increased by 67 %, with a sharp acceleration since the 1970s.

The development of renewable energy sources in recent years has failed to compensate humanity’s growing demand for energy. As a result, total CO2 emissions have grown over time to approximately 37-billion tons (37 Gt).

To reach carbon neutrality, the point at which CO2 concentration in the atmosphere stop rising, carbon capture, utilisation and storage technology (CCUS) has emerged as a promising solution to mitigate CO2 emissions and combat climate change. CCUS prevents CO2 from industrial processes and power generation facilities being released into the atmosphere. This helps mitigate climate change while enabling continued use of fossil fuels during the transition to renewable energy sources.

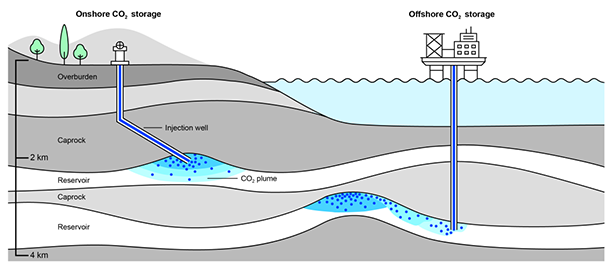

Permanent onshore and offshore solutions for storing CO2. [Source: IEA]

Principles of carbon capture

CCUS is an acronym that groups together all the carbon capture related technologies – available or under development – that can prevent CO2 from entering the atmosphere.

Captured CO2 can be transported via pipeline or transported in its liquid state by ship; it can be utilised in some industrial applications as a raw material to create other products, and excess captured CO2 can be injected and permanently stored in deep geological formations or depleted oil and gas reservoirs, which may be on land or offshore.

Today, only 45 Mt of CO2 are captured every year in about forty operational plants. Most of the captured CO2 is used in enhanced oil recovery (EOR) processes to improve oil and gas extraction.

Fifty new capture facilities are set to be operating by 2030, increasing the total capture capacity to 383 Mt/CO2/y. To be on track with the net zero emissions (NZE) scenario by 2050, however, the total capacity by 2030 should be at least 1 100 Mt/CO2/yr.

Carbon capture technologies

Carbon capture technologies can be classified into four main categories: pre-combustion capture, post-combustion capture, oxy-fuel combustion capture and direct air capture (DAC).

Pre-combustion carbon capture

Pre-combustion carbon capture allows for the removal of CO2 from a gas mixture before it is used, typically from syngas. Purified syngas can subsequently be burned to produce electricity using suitable gas turbines. This process can also be used to produce blue hydrogen or for natural gas sweetening after extraction.

Proprietary physical solvents used to capture the CO2 include Selexol and Rectisol, which work well at high concentrations of CO2 and can tolerate the presence of residual oxygen. The CO2 is then ….

Read more…

To access the full paper as published in African Fusion download the pdf from the link above.

To download and read the original paper from the voestalpine Böhler Welding website, click here.

Voestalpine Bohler Welding contacts

Enrico Zuin: enrico.zuin@voestalpine.com

Herbert Abbott: herbert.abbott@voestalpine.com

Nazmi Adams: nazmi.adams@voestalpine.com