Water, wastewater and industrial effluent facilities face increasing pressure to develop sustainable and smart solutions to meet rising water demand and to tackle environmental issues.

Click to download and read pdf

Recent advancements in water treatment technologies, including membrane filtration – reverse osmosis and nanofiltration – and electrochemical methods –electrocoagulation and electro-oxidation – have significantly improved treatment efficiency and water quality.

These technologies can deliver high-purity water and effectively remove contaminants. Additionally, advanced oxidation processes (AOPs) have proven highly effective in breaking down organic pollutants and treating emerging contaminants.

These smart systems, however, all need to be managed via smart monitoring for them to be fully effective.

Smart water

The integration of smart technologies into water infrastructure has paved the way for more efficient and resilient systems. Smart sensors and meters enable real-time monitoring of water quality and consumption, providing valuable data for predictive maintenance and for optimising water distribution. These technologies help detect leaks and inefficiencies promptly, reducing water loss and operational costs.

Artificial intelligence (AI) and machine learning (ML) are also playing a role in the water sector. By analysing vast amounts of data, AI and ML algorithms can predict demand patterns, optimise treatment processes, and improve decision-making. These technologies enhance the overall performance and sustainability of water infrastructure systems.

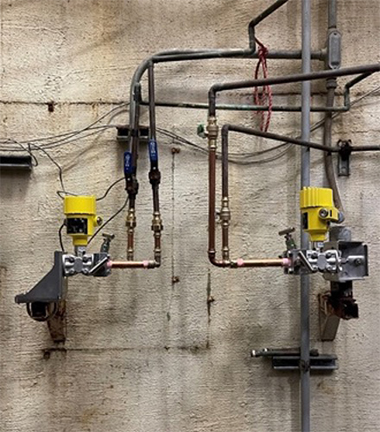

Smart sensors from VEGA

VEGA provides an extensive range of radar sensors that have the potential to transform the water industry. With a proven history of delivering precise level and pressure measurement solutions across diverse sectors, VEGA has showcased its proficiency in the water industry.

An individual VEGAPULS radar sensor, sanctioned by the German Water Resource Act (WHG) for overfill protection can simultaneously deliver both level measurement and overfill prevention. While redundant systems offer heightened security, VEGAPULS sensors fulfil all safety and accuracy criteria as independent devices, even in demanding conditions such as monitoring corrosive gases or turbulent water surfaces. The ‘Ü’ symbol on the sensor housing signifies WHG approval for overfill protection.

VEGAPULS sensors are minimally impacted by waves or turbulent water surfaces due to their wide dynamic range, enabling accurate measurement through the averaging of multiple reflected signals. For precise sludge level determination, however, the combination of a radar sensor with a pressure sensor proves effective.

The pressure sensor gauges the water level via hydrostatic pressure, with the variance between the two readings enabling the sludge thickness to be determined owing to its lower density compared to water. These sensors are available in various iterations, offering standard 4-20 mA output and cable versions with additional protocols such as Modbus for data logger integration. Tailored versions are also available, designed for SDI-12 communication commonly utilised in river and lake-level telemetry, for example.

Cable sensors, Modbus or SDI-12 outputs typically operate without the need for controllers. Unlike certain ultrasonic models, radar sensors function independently. Controllers can provide advantages, however, such as supplementary displays for on-site clarity, real-time pump control, and flow measurement with totalisation. VEGAMET digital field controller incorporate a data logger with an SD card capable of storing up to 100-million selectable measured values.

VEGA radar sensors are generally compatible with Zone 0 and Zone 1 hazard classifications for explosive environments and are available in intrinsically safe versions. Cable versions with encapsulation can be readily used in Zone 1 without the necessity of an inherently safe supply or barriers. These sensors are housed in plastic enclosures, a cost-effective and robust choice compared to the pricier metal housing mandated for flameproof enclosures. VEGA Radar sensors possess global approvals to meet generic ex-area requirements.

Radar vs ultrasonic sensors

Radar technology provides pricing comparable to ultrasonics but offers better performance across a wider range of applications. As a result, making the switch to radar sensors is generally recommended.

Looking into the future, the water infrastructure sector must prioritise innovation and sustainability. Collaboration between governments, industries and research institutions is vital to propel further advancements. Investing in research and development and embracing cutting-edge technologies will be essential to tackle future water challenges and secure a sustainable water supply for generations to come.

VEGA has long history of innovation and is recognised as a global leader in measurement technology. Dedicated to precision and reliability, the company’s sensors and instruments are known for setting new benchmarks in accuracy, durability and performance.